-

Sherry

Hi there! Welcome to my shop. Let me know if you have any questions.

Sherry

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Matching Your Crusher Type with the Right Pedestal Rock Breaker Boom System

2025-07-24 17:35:05

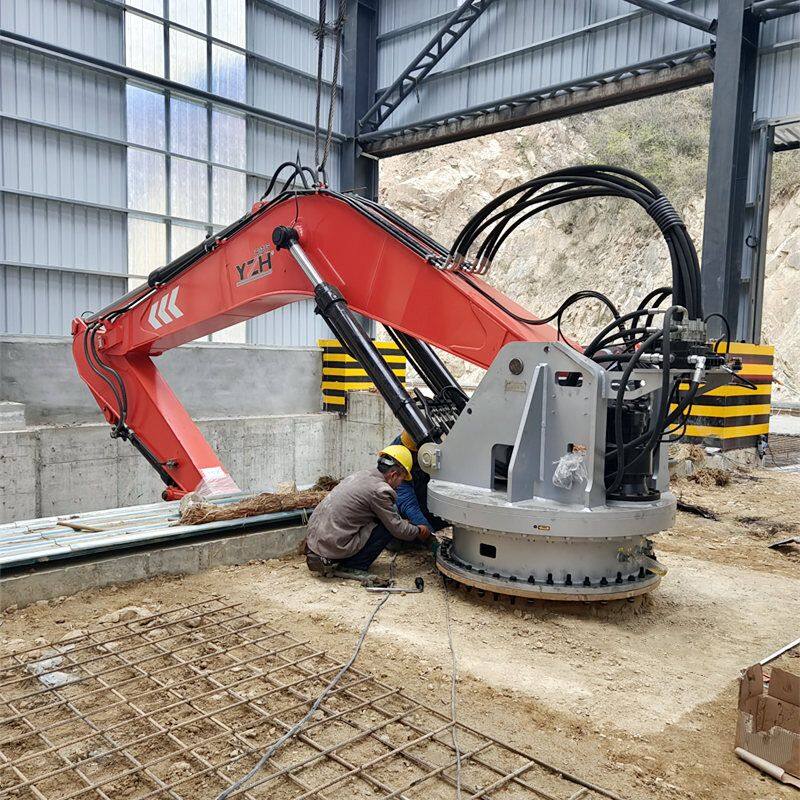

Matching Your Crusher Type with the Right Pedestal Rock Breaker Boom System

Choosing the right pedestal rock breaker boom system isn’t just about reach or breaker size—it’s also about compatibility with your crusher type. Each type of primary crusher presents different physical layouts, feed mechanisms, and blockage characteristics. Matching the breaker boom system to the crusher ensures smooth operations, fewer disruptions, and extended equipment life.

Here’s how to select the right system based on your crushing equipment:

1. Jaw Crushers (Primary Crushing Stations)

Typical Challenges:

Irregular oversize rocks block the feed opening

Large gap between grizzly screen and jaw inlet

Blockages often occur at the top of the chamber

Recommended Boom Setup:

Long horizontal reach, moderate vertical swing

Mount boom to cover grizzly bars and the jaw mouth

Medium-duty breaker with controlled impact force to avoid jaw damage

Control Preference:

Remote joystick (line-of-sight) or integrated into control tower

2. Gyratory Crushers

Typical Challenges:

Large volume flow and deep throat

Bridging occurs mid-way in the crushing chamber

Material buildup around the spider or mantle area

Recommended Boom Setup:

Heavy-duty boom with deep vertical reach

Top-down strike capability

Breaker positioned to access both chamber and spider rim area

Control Preference:

Wireless remote or PLC-integrated automation for centralized control

3. Hammer Crushers / Horizontal Impact Crushers

Typical Challenges:

Breaker use often needed upstream (pre-feed) rather than inside crusher

Less prone to blockages but more sensitive to uncrushed tramp material

Recommended Boom Setup:

Smaller boom, mounted over feeder or conveyor inlet

Breaker used to size material before entry

Control Preference:

Manual or semi-remote control, depending on blockage frequency

4. Grizzly Screens (Standalone or Crusher-Feed)

Typical Challenges:

Oversized rocks bridging across bars

Material stuck before reaching the crusher

Recommended Boom Setup:

Wide horizontal swing to clear broad grizzly surface

Mount to cover full width of the feeder

Fast, repeatable breaker strokes with accurate targeting

Control Preference:

Remote control with camera-assist if visibility is limited

5. Mobile Crushing Units

Typical Challenges:

Compact layout, limited mounting options

Transport constraints require foldable or lightweight systems

Recommended Boom Setup:

Compact, low-profile boom

Bolt-on systems designed for easy removal or repositioning

Breaker with fast response and low energy consumption

Control Preference:

Wireless remote with mobile control panel

The key to selecting the right rock breaker boom system isn’t just in the specs—it’s in understanding how your crusher behaves, where blockages happen, and what type of intervention is safest and fastest.

Choosing a system that aligns with your crusher type helps you:

Reduce unplanned downtime

Improve material flow efficiency

Extend the life of both crusher and breaker

Consult with a specialist or manufacturer who understands both your crusher design and site layout to tailor the optimal solution.

Tags: rock breaker boom system, pedestal rock breaker boom, boom system